The use of magnesium oxide in the composition of refractory masses in the steel industry ensures their integrity when exposed to extreme heat.

Because it is capable of withstanding extremely high temperatures, magnesium plays a crucial role in the manufacture of refractory masses, making them more resistant and durable in high temperature environments.

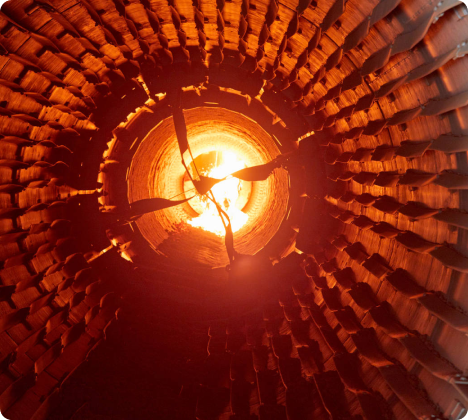

Therefore, it becomes very suitable for applications in industrial furnaces and refractory linings, ensuring that production takes place without compromising the equipment.

Magnesium oxide is chemically stable at high temperatures and does not react easily with other materials, maintaining the integrity of the refractory mass in hostile environments.

Furthermore, it also works as a very effective thermal insulator, helping to maintain heat within systems such as furnaces and boilers.

Magnesium oxide has a high resistance to thermal shock because it has low thermal expansion, that is, it expands and contracts very little when faced with temperature changes.

Therefore, magnesium oxide is added to the composition of refractory masses to reduce the risk of cracks and cracks in them.

Magnesium oxide is the result of calcining raw magnesite (magnesium carbonate) in a vertical or horizontal furnace at an average temperature of 900oC, resulting in products with up to 92% MgO content.

Magnesium has two Magnesium Oxide lines known as CCM M and CCM P, which have a wide range of grain sizes, with sieved and ground materials.

Active Magnesium: 200 mesh; 325 mesh 53% – 55%

Packaging: 25kg sack with pallet and Big Bag up to 1.350Kg

Magnesium carbonate is a chemical compound with the formula MgCO3. Magnesium has two lines of Magnesium Carbonate known as MAG - M and MAG - P, which have a wide range of particle sizes.

Purity content: 42% – 45% Magnesium Oxide (MgO)

Magnésio Ativo: 25% – 28%

Sintered magnesium oxide is the result of the sintering process of raw magnesite (magnesium carbonate) at a temperature of 1800oC. Our products are the result of single firing in vertical furnaces. Our Sintered Magnesium Oxide product lines are known commercially as DBM M and DBM P and have an MgO content of up to 94%.

Granulometry Sieved: 0,0 a 0,2mm; 0,2 a 0,5 mm; 0,5 a 1,0 mm; 1,0 a 2,0 mm; 2,0 a 3,0 mm; 3,0 a 4,0 mm

Granulometry Ground: 200 mesh; 325 mesh

Density: 2,95g/cm3 e 3,05g/cm3

Packaging: Big Bag de até 2.000Kg, Sacos de 25Kg c/ pallet e Granel

Erro: Formulário de contato não encontrado.